You are here :

ADDITIVE MANUFACTURING

The community is founded on the belief that additive manufacturing significantly impacts industries, societies, energy consumption, and carbon emissions. This technology has numerous applications in aerospace, automotive, medical, art, retail, consumer goods, and now, construction.

However, what underlying concepts, processes, materials, benefits, and limitations must be addressed? Several current issues confront additive manufacturing and its applications, including material challenges, cost, intellectual property, and sustainability, remain unresolved.

Researchers and educators within the learning community aim to introduce a disruptive approach by exploring material technology, processes, machine tools, applications in natural and applied sciences, and design management. This goal will be achieved through interactive cross-campus guest lectures and student projects that investigate and redefine the design and use of additive manufactured objects in our societies.

This learning community intends to provide students and participants with a comprehensive understanding of additive manufacturing, its inherent processes, and recent advancements, as well as the challenges that must be addressed to fully realize its potential.

Learning Community Activities

- Past Events

-

- 3D printing of construction materials: challenges and issues

November 6th 2023

By Alexandre Pierre (CY Cergy Paris Université)

This guest lecture will show the last news and insights of 3D printing projects in the construction area. Nevertheless, this process can have impacts on costs, training of construction actors, choice of materials, and also on the environment. This guest lecture will therefore demonstrate the potential of 3D printing of construction materials.

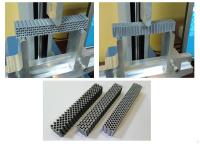

- On the mechanical behaviour of 3D printed honeycomb structures

May 11th 2023

Lect. dr. eng. Vasile Cojocaru (Babeș-Bolyai University).

The additive manufacturing technologies facilitates the development of components with a cellular core structure. These structures reduce the weight of parts and the material consumption. The presentation focuses on the analysis of the mechanical behavior of some structures with cellular core. Case studies of loading along the principal axes of inertia and asymmetric loading are analyzed.

- Textile Reinforced Concrete: An introduction to material innovations enhancing novel structures

December 5th 2022

Prof. Tine Tysmans (Vrije Universiteit Brussel).

As the most-used man-made material across the globe, concrete is everywhere, but this popular building material presents significant challenges related to its huge environmental impact and limited durability properties. Textile Reinforced Concrete (TRC) could provide a solution to these challenges, and hence could potentially revolutionize the way concrete is currently being used as a construction material.

In TRC, the traditional steel reinforcement is fully replaced by fibre textiles. The use of this innovative reinforcement has two important advantages: (i) the concrete cover, traditionally required to prevent the steel reinforcement from corroding, can be omitted and hence the thickness of concrete elements can be drastically reduced, and (ii) the flexibility of the fibre textile reinforcement allows to easily manufacture cutting-edge concrete structures with complex shapes. This introductory lecture situates Textile reinforced concrete as a structural material compared to polymer-matrix composites and steel-reinforced concrete. It discusses also several interesting novel structural concepts in which the material is used at its best.

- Overview of additive manufacturing in the construction sector

November 22nd 2022.

Associate Professor Alexandre Pierre (CY Cergy Paris Université).

The European construction sector produces almost 2 billion tons of waste per year. Many projects that use digital or automated processing of concrete emerged during the last decade. This layer-by-layer production allows high complex structures without the need of formwork. This could lead to a high material saving potential at same load bearing capacity. However, the digital fabrication has not been fully transferred to concrete construction industry although additive manufacturing (3D printing) processes of concrete and cement-based materials could bring architectural and structural innovation. We propose in this guest-lecture an overview of the additive manufacturing of construction materials.

How to get involved?

(Students and educators)

Contact the community lead Alexandre Pierre (alexandre.pierre@cyu.fr) or the local facilitator Tomy Quenet (tomy.quenet@cyu.fr).

Learning Community Members

- Lead: Alexandre Pierre (CY). Email: alexandre.pierre@cyu.fr

-

Alexandre PIERRE joined the Department of Civil Engineering and the laboratory of mechanics and civil engineering at CY Cergy Paris University as an Associate Professor in September 2014.

Alexandre PIERRE’s research interests are in the area of construction materials, in particular rheology and processing using additive manufacturing techniques such as 3D printing.

Recent efforts include investigating selective binding techniques and the integration of bio-based materials. - Partner: Tine Tysmans (VUB). Email: Tine.Tysmans@vub.be

-

Tine Tysmans is an associate professor at the Vrije Universiteit Brussel, dept. Mechanics of Materials and Constructions. She graduated as Civil Engineer in 2006 and received her PhD degree - as a PhD-Fellow of the Research Foundation Flanders - in 2010 on the topic of thin shell structures in textile reinforced cement composites. Tine Tysmans is teaching courses within the field of Structural analysis, Structural design, Mechanics, and Lightweight cement composite structures.

Her research is on resource-efficient lightweight structures such as shells, scissor structures or sandwich panels, often using cement composites. She studies their mechanical performance by means of experimental testing, numerical modelling, form finding and structural optimisation.

In the past she was a visiting researcher at Princeton University (USA) and ENISE Saint-Etienne (France). She is an active member of two RILEM technical committees (MCC-Mechanical characterization and structural design of textile reinforced concrete and IMC-Durability of inorganic matrix composites used for strengthening of masonry constructions). She was and is involved in several international joint PhDs with University of Patras (Greece), Jimma University (Ethiopia) and CY Cergy Paris Université (France), the latter within the Eutopia framework. - Partner: Joško Valentinčič (UL). Email: jv@fs.uni-lj.si

-

Joško Valentinčič is an associate professor at the University of Ljubljana, Faculty of Mechanical Engineering. He was involved in development of machining processes and monitoring and control systems using robust design of experiments methods, inductive machine learning and neural networks. Currently he is working on additive manufacturing technologies focusing on using bio-based upcycled materials in 3D printing and 3D printing of soft tool inserts for micro injection moulding. He is also collaborating with Slovenian national building and civil engineering institute on 3D printing of concrete.

- Partner: Damjan Klobčar (UL). Email: damjan.klobcar@fs.uni-lj.si

-

Damjan Klobčar is an associate professor at the Department of Materials Technology at the Faculty of Mechanical Engineering, University of Ljubljana. He is the head of the Laboratory of Welding and Joining. He teaches the subjects: "Welding and Joining Techniques", "Weldability of Materials", "Additive Manufacturing of Metals" and "Materials and Welding". His research interests include various welding and joining technologies (FSW - Friction stir welding, TIG welding, MIG / MAG welding, laser welding, ultrasonic welding of metals and polymers, robotic welding, brazing, and soldering, adhesive bonding), weldability of materials, additive manufacturing, arc additive manufacturing, welding process monitoring, and advanced characterization of materials and welds. Based on the research topics, he is involved in repair welding of industrial tooling, development of joining technologies for production of e.g. heat exchangers, battery systems, electrical contacts, development of arc additive manufacturing technology and assembly of sensors and devices using ultrasonic welding. He is a co-leader of the Vanguard Initiative's 3DP Pilot demo case Innovative hybrid (subtractive/additive) manufacturing processes for repairing added value damaged objects.

- Partner: Deja Muck (UL). Email: deja.muck@ntf.uni-lj.si

-

Deja Muck received her PhD in Graphic and Interactive Communication from the University of Ljubljana, Faculty of Natural Sciences and Engineering, Department of Information and Graphic Technology. Dr. Muck worked in the past on the development of paper coatings used especially for inkjet printing. Her current research focuses on printed electronics, particularly their use in print media and packaging in combination with interactive technologies. In recent years, she has also focused on the field of 3D technologies and 4D printing. She works as a full professor at the Faculty of Natural Sciences and Engineering in Ljubljana, Slovenia.

- Partner: Niels De Temmerman (VUB). Email: Niels.De.Temmerman@vub.be

-

Prof. dr. ir. arch. Niels De Temmerman (°1977) is full time Associate Professor at the Department of Architectural Engineering of the Vrije Universiteit Brussel. He is an architectural engineer (2002) with a PhD on deployable scissor structures (2007). Within the VUB Architectural Engineering research group, he is co-leading the research on Circularity and Transformable Structures since 2009. Both in research and education his main expertise entails the design and analysis of transformable structures (deployable structures and kit-of-parts systems) for architectural applications, design for disassembly and circular/sustainable construction. Niels teaches architectural design and parametric design and has a keen interest in digital fabrication, including 3D-printing. In recent years, he conducted research as a Velux visiting professor at the Royal Danish Academy of Fine Arts in Copenhagen.In 2018 he co-founded a VUB-spin-off called Konligo, focusing on the creation of deployable scissor structures for a zero-waste event sector and in 2019 he co-realised the Circular Retrofit Lab, a demonstrator building for Circular Building at the VUB-campus.

- Partner: Vasile Cojocaru (UBB). Email: vasile.cojocaru@ubbcluj.ro

-

Vasile Cojocaru is a lecturer at Babeș-Bolyai University, Faculty of Engineering. His main subjects are Strength of Materials and Computer Aided Design. Vasile Cojocaru's research areas include: characterization of the mechanical behavior of metallic, polymeric and composite materials; numerical analysis of the static and dynamic behavior of mechanical system components. He is currently involved in research related to the mechanical behavior of 3D printed parts (influence of process parameters on mechanical properties, honeycomb structures, topology optimization).